- What Is Ceramic Coating?

- Ceramic Coating Cure Time Chart

- Factors That Influence Ceramic Coating Curing Time

- Typical Curing Timeframes for Ceramic Coatings

- Why Proper Curing Is Crucial for Ceramic Coats

- Tips to Accelerate the Ceramic Coating Curing Process

- Common Myths About How Long Ceramic Coating Takes to Cure

- DIY vs Professional Ceramic Coating Application

- Should You Drive Your Car After Ceramic Coating?

- How Long Does Ceramic Coating Take to Cure?

- Conclusion

- Frequently Asked Questions on Ceramic Coating Cure Time

Have you ever gotten your car ceramic coated and wondered how long you'd have to wait before hitting the road? Ceramic coating cure time is crucial to get those glossy, protective benefits, but the wait can feel like an eternity. What factors determine the curing timeframe? Is there any way to speed it up? How do you know when it's ready? Don't sweat it, we've got the down-low on everything you need to know about how long ceramic coating takes to cure. We'll break it down so you can cruise confidently with a fully cured ceramic coating that's ready to flex its shiny muscles. From temperature and humidity to the type of ceramic coating used, we'll cover all the elements that influence curing so you can decide if it's worth the wait or if you should pony up for faster curing. And if patience isn't your strong suit, we'll share pro tips to accelerate curing time without botching the job. Let's hit the road and get to the bottom of that lingering question - how long does ceramic coating take to cure?

What Is Ceramic Coating?

Ceramic coatings are protective layers made of silicon or quartz crystals applied to vehicle paint. We use them to shield our car’s finish from environmental damage while enhancing the appearance. Unlike wax, ceramic coatings bond directly to the vehicle's clear coat, creating a rigid shell.

The main benefits of ceramic coating are durability and protection. A quality ceramic coating can last for years with proper maintenance. It protects the paint from UV radiation, scratches, stains, and oxidation. Ceramic coatings also cause water and chemicals to bead up and slide off the surface, taking dirt and debris with them. This effect is known as hydrophobicity and helps keep vehicles cleaner.

There are several types of ceramic coatings to choose from. Some are DIY-friendly and wipe on like wax, while others are professionally installed. Professionally installed coatings tend to last longer but often cost more. The curing process also varies between products, ranging from a few hours to several days. Curing is when the coating hardens and bonds fully to the paint. Allowing adequate curing time is essential to maximize the coating's durability and protection.

Ceramic coatings have gained popularity in recent years thanks to their longevity and protective benefits. When properly maintained, a ceramic coating is one of the best ways to shield your vehicle's paint and keep it looking like new for years to come. While application and curing processes can differ between products, the end result of a durable, high-gloss finish is well worth the investment for many car owners and enthusiasts.

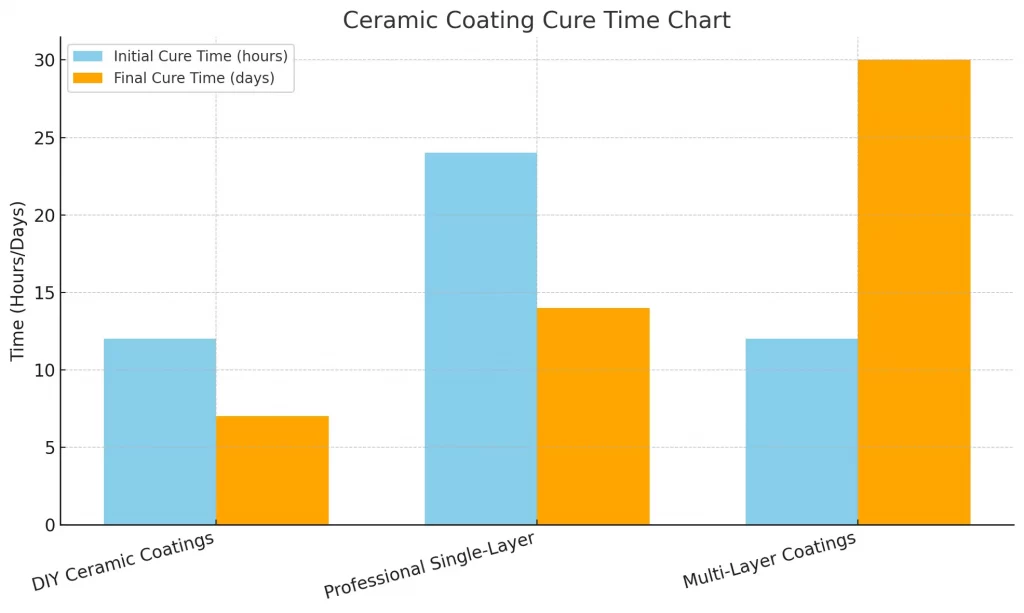

Ceramic Coating Cure Time Chart

The cure time for ceramic coatings depends on various factors, such as the type of coating, environmental conditions, and the number of layers applied. Below is a detailed ceramic coating cure time chart to guide you:

| Coating Type | Initial Cure Time | Final Cure Time | Key Notes |

|---|---|---|---|

| DIY Ceramic Coatings | 12-24 hours | 5-7 days | Avoid washing or exposing to harsh elements. |

| Professional Single-Layer | 24-48 hours | 7-14 days | Curing can continue to strengthen for up to 30 days. |

| Multi-Layer Coatings | 12-24 hours per layer | 10-30 days | Allow time between layers, longer-lasting results. |

Factors That Influence Ceramic Coating Curing Time

As passionate car owners, many of us are eager to get our vehicles back after a ceramic coating treatment. However, patience is key. The curing process is crucial to achieving maximum performance and durability from your ceramic coating. Several factors determine how long it takes for a ceramic coating to fully cure.

Type of Ceramic Coating

The specific formula used in a ceramic coating directly impacts its curing timeframe. Coatings with higher concentrations of silicon dioxide and titanium dioxide, which create a harder finish, typically require longer to cure. Multi-layer coatings also need more time between applications and for the final cure.

Temperature and Humidity

Weather conditions are significant contributors to curing time. Warmer temperatures speed up the chemical reaction required for curing while cooler temperatures slow it down. High humidity also accelerates curing. The ideal conditions for the fastest cure are temperatures of 70 to 80 F and 40 to 60% relative humidity.

Application Method and Thickness

How a ceramic coating is applied affects its curing time. Spray-on coatings usually cure faster than wipe-on or dip coatings since they can be applied in very thin, even layers. The number of layers also matters; more layers mean a longer curing time. Thicker coatings need the most time to cure as it takes longer for the chemical reaction to penetrate the entire coating.

Curing Times in the Real World

As a general rule of thumb, most standard professional-grade ceramic coatings require 12 to 24 hours of cure time between layers and at least 2 to 5 days for the final cure. However, curing can continue to strengthen the coating for up to 30 days. For example, Gtechniq Crystal Serum Light requires a minimum of 24 hours cure time per layer and 7 days for full hardness while Opti-Coat Pro+ needs 12 to 24 hours between layers and 3 to 7 days total curing.

While the waiting period may seem lengthy, proper curing helps ensure you get the best results. By understanding how various factors affect the curing process, you can choose a ceramic coating that fits your needs and patience level. With the right formula and conditions, you'll be enjoying the benefits of your ceramic coating in no time.

Typical Curing Timeframes for Ceramic Coatings

When we first got our cars ceramic coated, we were eager to see the results. But we quickly learned that ceramic coating is not an instant process—it requires time to fully cure to achieve maximum hardness and protection. The curing time can vary depending on several factors, including the type of ceramic coating used, temperature and humidity, and the application method. Know about What Are the Costs and Benefits of Ceramic Coating?

DIY vs Professional Application

If we applied the ceramic coating ourselves, we can expect a longer curing time of up to several days to as much as a week for the coating to fully harden, depending on the product used. Professional detailers have controlled environments and professional-grade equipment that can accelerate the curing process to within 24 to 48 hours. The pros also have the proper training to apply the coating efficiently and effectively, ensuring full and even coverage in fewer coats, which also speeds up curing.

Environmental Conditions

Warmer temperatures and lower humidity are ideal for curing ceramic coatings. Curing times are usually faster in the summer compared to winter. If we run a space heater in our garage or apply a ceramic coating to a vehicle stored in a garage, it will cure faster than on a vehicle exposed to cooler ambient temperatures.

Coating Thickness

The more coats of ceramic coating we apply, the longer it will take to cure. Most DIY ceramic coating kits recommend applying 2 to 3 coats for best results, with curing times of 12 to 48 hours between coats. More coats mean longer wait times, but also more protection and durability.

By being patient and allowing the proper curing time recommended for our specific ceramic coating product and application, we'll achieve the hardest, glossiest finish and longest-lasting protection for our vehicles. The wait is well worth the results! Following the guidelines and avoiding the temptation to accelerate the curing process will help ensure we get the most out of our ceramic coating.

Why Proper Curing Is Crucial for Ceramic Coats

When we get our vehicle ceramic coated, we’re investing in a durable paint protection system. But to get the most out of this investment, we have to be patient through the curing process. Curing simply means giving the ceramic coating enough time to fully harden and bond to the vehicle’s paint. This typically takes anywhere from 12 to 72 hours, depending on the product and environmental factors. As eager as we are to show off our newly ceramic-coated ride, rushing the curing time can compromise the coating and reduce its protective abilities. Want to know the Benefits of Ceramic Coating for Cars?

Temperature and Humidity Matter

Curing time is heavily influenced by the surrounding temperature and humidity. Warmer, more humid conditions will accelerate the curing process, while cooler or dryer air will prolong it. The product directions will specify the ideal temperature range for curing—be sure to ceramic coat your vehicle in conditions that will allow it to cure within this range. Using heat lamps or space heaters can help speed up curing in some situations.

Thicker Coats Take Longer

The more coats of ceramic coating you apply, the longer it will take to cure. Most DIY ceramic coatings require 2-3 coats for good coverage, while professional applications may use 3-5 coats. As a general rule, allow 12-24 hours between coats and 24-48 hours after the final coat before driving or washing the vehicle. The curing isn’t complete for up to a week, so avoid any harsh chemicals or abrasive washes during this time.

Professional vs. DIY Application

If you opt for a professional ceramic coating application, the detailer will ensure proper curing conditions and timeframes for their specific products. DIY application at home provides more flexibility but also more opportunities for error, like applying too thick of coats or not allowing enough time between coats. For the best results with a DIY ceramic coating, carefully follow the directions provided with your product and do not rush the curing process. The patience will be well worth it in the end!

Tips to Accelerate the Ceramic Coating Curing Process

When we applied ceramic coating to our cars, we were eager to get out on the road and show off the shiny, slick finish. However, patience is key. Ceramic coating needs time to fully cure to achieve maximum hardness and durability. While the typical curing time is 12 to 48 hours, there are a few tricks we’ve learned to help speed up the process without compromising the results.

Increase the Temperature

Heat causes the chemical reaction in ceramic coatings to accelerate, so raising the temperature of the coated surface will speed up curing. We placed portable space heaters in the garage to keep the temperature around 85 F. The heat lamps mechanics use also work great for targeted areas. Just be very careful to avoid overheating, which can damage the coating.

Use an Infrared Lamp

Infrared lamps emit a wavelength of light that generates heat. When focused on the coated vehicle, they can significantly increase the surface temperature to speed curing. We purchased an inexpensive infrared lamp and kept it at least 2 feet from the surface, moving it around to evenly heat all areas. Again, be cautious not to overheat the coating.

Apply Thinner Coats

The more product you apply, the longer it will take to cure. We applied ceramic coating in multiple thin coats, waiting 20 to 30 minutes between applications. This allowed each coat to start curing before the next application, so by the time we finished, the initial coats had already started to harden. In total, we did 4 to 6 thin coats for good coverage and quick curing.

Increase Humidity

For ceramic coatings that cure through a chemical reaction with moisture in the air, increased humidity will accelerate the process. We used humidifiers in the garage to boost the humidity to around 50-60% for quicker curing. The added moisture in the air helps the coating cure faster.

Following these tips, we were able to reduce the curing time for our ceramic coating by up to 50% without compromising the results. However, we still gave it a minimum of 6-12 hours before driving the vehicles to ensure maximum hardness and durability. Patience does pay off!

Common Myths About How Long Ceramic Coating Takes to Cure

We’ve all heard various myths about how long it takes for ceramic coating to fully cure. As enthusiasts who have used these coatings ourselves, we want to clear up some of the misinformation out there.

Myth #1: Ceramic coating is cured as soon as it’s applied

This is false. Ceramic coatings require time to chemically bond to your vehicle’s paint, which is the curing process. Most coatings take 12 to 48 hours to cure, depending on factors like temperature and humidity. During this time, it’s best to avoid washing or driving your car.

Myth #2: You can’t wash your car for weeks after application

While you should avoid washing for 12 to 48 hours after application while the coating cures, you can typically wash your car again after that initial period. In fact, the first wash after curing is important to remove any residue left over from the application process. You do want to avoid harsh chemicals for the first few washes, but a normal wash with car wash shampoo and water is fine after the coating has cured.

Myth #3: Ceramic coatings never need to be reapplied

Ceramic coatings are durable, but they do slowly degrade over time. Most coatings last 2 to 5 years before needing a "booster" or reapplication to restore protection. Environmental factors like lots of sun exposure, acidic rain and snow, and high-mileage driving can accelerate the breakdown of a ceramic coating. For the best protection, it's a good idea to inspect your vehicle's coating annually and reapply as needed.

The curing process is a crucial step for ceramic coatings to reach maximum hardness and durability. By avoiding these common myths and allowing proper curing time, you'll get the best performance and longest lifespan from your ceramic coating. The wait may seem long, but the protection and shine it provides your vehicle makes it well worth it!

DIY vs Professional Ceramic Coating Application

When it comes to applying ceramic coating, we have a choice to make: should we do it ourselves or hire a professional? As with many things, there are pros and cons to both options.

DIY Ceramic Coating

Doing it ourselves saves money and allows us to learn a new skill. We can take our time to do the work thoroughly. However, ceramic coating application requires patience and precision. Without proper training and experience, it’s easy to end up with an uneven, blotchy finish or miss spots altogether. We also have to invest in high quality products and tools to get good results. For many of us, the time and hassle outweigh the cost savings.

Professional Ceramic Coating Services

Professional detailing services in Portland have the proper training, experience, and equipment to apply ceramic coatings correctly. They use high quality, commercial grade products to ensure an even, durable finish. The work is also guaranteed, so if there are any issues with the coating, they will re-do it. Of course, professional services come at a premium cost. The total charge will depend on the specific vehicle and number of coats applied but typically ranges from $500 to $1500.

For most vehicle owners looking to protect their investment, professional ceramic coating application is the best choice. While DIY may seem appealing, the risk of ending up with a subpar finish and wasting money on products is high. Professionals have the skills and tools to do the job right the first time, leaving us with a showroom-quality coating and peace of mind. For the extra cost, professional ceramic coating application is worth the investment.

Should You Drive Your Car After Ceramic Coating?

When we get our cars ceramic coated, the excitement of seeing that glossy, slick finish can make us eager to get out on the road right away. However, the coating needs adequate time to cure to reach maximum hardness and durability. As tempting as it is to take our newly-coated rides for a spin, driving too soon can damage the coating and impact how well it protects the paint.

As DIY detailers, we understand the desire to get instant gratification from our work. But by allowing the proper cure time, we’ll get to enjoy the benefits of ceramic coating for years to come. The exact curing period depends on factors like temperature, humidity, and the specific product used. In general, most ceramic coatings need 12 to 24 hours to dry to the touch, but 7 to 14 days to fully cure.

During the curing process, the coating is still bonding to the clear coat and hardening. Driving before it’s fully cured means the coating hasn't reached maximum hardness and scratch resistance. This can lead to swirl marks, scratches, and reduced gloss. The coating is also more prone to water spotting in the first few days, and any water left on the coating during this time may etch into the surface.

We know how tough it is to resist getting out on the open road with our newly ceramic-coated rides. But by exercising patience for a couple of weeks after application, the coating can properly cure to deliver the ultimate protection and shine we want. Our vehicles have never looked this good, so they deserve the best care and treatment. By waiting until the coating is fully cured, we'll get to enjoy it looking showroom new for years to come. The extra days of waiting will be well worth it!

How Long Does Ceramic Coating Take to Cure?

We know how eager you are to get your vehicle back on the road after a ceramic coating treatment. However, allowing adequate time for the coating to cure is crucial to achieving maximum durability and protection. As a general rule of thumb, most ceramic coatings require 12 to 48 hours to fully cure, depending on the specific product and environmental factors.

The curing process refers to the chemical reaction that occurs as the coating hardens and bonds to your vehicle's paint. During this time, the coating is still soft and malleable. Driving or washing your vehicle too soon can lead to swirl marks, scratches or water spots that become permanently etched into the coating. For the best results, follow your detailer’s recommendations regarding curing times. They have experience with the products used and your local climate conditions.

Some coatings cure faster than others due to differences in chemical composition. For example, quartz-based or polysilazane coatings typically cure within 12 to 24 hours. Ceramic polymer coatings, on the other hand, can require 24 to 48 hours to fully harden. Warmer temperatures and lower humidity will also accelerate the curing process. If conditions are ideal, some coatings may cure in as little as 8 to 12 hours. However, when in doubt, it is best to be patient.

While waiting for your ceramic coating to cure can require some patience, the rewards are well worth it. A properly cured coating will provide exceptional protection and durability for years to come. It will be harder, more glossy and resistant to scratches and environmental damage. An insufficiently cured coating, on the other hand, can start to fail within a few months, requiring costly re-coating to correct.

When applied by a professional, ceramic coating are a premium upgrade that deserves a premium curing process. Trust that waiting an extra day or two to hit the road will provide maximum return on your investment. Your vehicle's paintwork will thank you for it!

Conclusion

When it comes to ceramic coating, the curing process is one of the most important steps to get right. We’ve applied a coating to protect our vehicle’s paint, but if we don’t give it adequate time to fully cure, it won’t harden and bond properly. This means it won’t be as durable or long-lasting as promised.

As a general rule of thumb, most ceramic coatings need at least 24 to 48 hours to cure before driving the vehicle or exposing it to moisture. The exact time will depend on factors like the specific product used, temperature and humidity levels, and thickness of application. It’s best to follow the guidelines provided for your particular coating to ensure optimal results. If possible, keep the vehicle in a garage during the curing period.

Some people try to speed up the curing process using heat lamps, space heaters or heat guns. While these techniques can accelerate curing, they also increase the risk of defects forming in the coating. It’s really best to be patient and allow the natural curing time. Your patience will pay off with a strong, durable coating that looks great and lasts for years.

There are a few common myths about curing times for ceramic coatings that we wanted to clear up. No, you don’t need to wait weeks before driving or washing your vehicle. No, over-curing the coating won’t cause damage. And no, you can’t instantly test if the coating is cured by wiping it with a solvent. Curing happens at a molecular level and the surface may feel dry to the touch before fully curing. The only way to properly test is with a hardness tester, or by waiting the recommended time.

When done correctly, a professionally-applied ceramic coating with adequate curing time will provide an incredibly durable, long-lasting finish for your vehicle. The results are well worth the wait! Take the time to do it right and you’ll enjoy the benefits for years to come. Contact us today for your car ceramic coating services in Portland.

Frequently Asked Questions on Ceramic Coating Cure Time

When it comes to freshly painted cars, a common question is, how long does it take for car paint to cure? Typically, the curing process can take anywhere from 24 hours to a few weeks, depending on the type of paint, weather conditions, and the curing method used.

The ideal ceramic coating cure temperature is between 60°F and 85°F (15°C - 29°C), as extreme cold or heat can extend or reduce curing times.

Some professionals use infrared curing lights to speed up the process while ensuring the coating hardens thoroughly.

While the initial drying phase might only take a day or two, car paint takes 30 to 90 days to fully cure under optimal conditions. During this period, the paint hardens completely, achieving maximum durability and protection.

If not fully cured, the coating may not deliver its full protective benefits and could deteriorate faster when exposed to moisture or contaminants.

Revive your ride anytime, anywhere

Schedule AppointmentQuestions? Call us now!